Wednesday, 31 May 2017

What is Scratch

Scratch is a free visual programming language developed by the MIT (Massachusetts Institute of Technology) Media Lab. Scratch is used by students, scholars, teachers, and parents to easily create animations, games, etc. It provides a stepping stone to the more advanced world of computer programming. It can also be used for a range of educational and entertainment constructionist purposes from math and science projects, including simulations and visualizations of experiments, recording lectures with animated presentations, to social sciences animated stories, and interactive art and music.Viewing the existing projects available on the Scratch website, or modifying and testing any modification without saving requires no online registration.

Scratch allows users to use event-driven programming with multiple active objects called sprites.[Sprites can be drawn, as vector or bitmap graphics, from scratch in a simple editor that is part of Scratch, or can be imported from external sources, including webcams.

As of 2013, Scratch 2 is available online and as an application for Windows, macOS, and Linux (Adobe Air Required). The source code of Scratch 1.x is released under GPLv2 license and Scratch Source Code License.

Scratch also has its own wiki, available at https://wiki.scratch.mit.edu for members of the online community to use when unclear about features of Scratch. It covers blocks, parts of the program, features of the website, etiquette in the community, and more.

Scratch allows users to use event-driven programming with multiple active objects called sprites.[Sprites can be drawn, as vector or bitmap graphics, from scratch in a simple editor that is part of Scratch, or can be imported from external sources, including webcams.

As of 2013, Scratch 2 is available online and as an application for Windows, macOS, and Linux (Adobe Air Required). The source code of Scratch 1.x is released under GPLv2 license and Scratch Source Code License.

Scratch also has its own wiki, available at https://wiki.scratch.mit.edu for members of the online community to use when unclear about features of Scratch. It covers blocks, parts of the program, features of the website, etiquette in the community, and more.

Tuesday, 30 May 2017

Training Tuesday # 5 how to solder surface mount components

Welcome to another Training Tuesday this week will talk about surface mount components

Surface mount components can be very hard to solder so I hope this will help

2. PCB(Printed Circuit Board) with available pads

3. SMD (Surface Mount Device) component that matches the available pad

4. Solder (recommend water soluble, rosin core acceptable)

5. Desoldering braid

6. Flux w/ applicator

7. Tweezers

8. Rubbing alcohol (rosin core solder) OR

9. Water (for water soluble solder)

10. Anti-static cloth

2. Clean the PCB of any dust or debris.

3. Turn the soldering iron on now, and set the temperature between 600-700 degrees.

Warning: When heated to these temperatures, you will be burned if you touch the tip of the soldering iron.

Align the pins of the component with the pads on the circuit board using tweezers. Since most surface mount components have the same amount of pins on both sides, it is important to find "pin 1" every time you place a new component.

2. By now, the soldering iron should be hot. Get a small to medium sized dot of solder on the tip.

3. Pick any corner pin on the component

4 . Touch and hold the soldering iron to the pad that will be associated with that pin.

5. If you have done this correctly, the solder should have transferred from the pad on the circuit board to the component pin, it does not matter if you have connected excess pins, this will be fixed later.

1. This substance is messy, so be sure to use an applicator. (toothpick, brush, etc.) In this case, I have used a metal tip.

2. Get a large amount of flux on the applicator.

3. Spread the flux over the pins on the opposite side of the component that was tacked down in the previous step.

Surface mount components can be very hard to solder so I hope this will help

Useful tools

1. x1 soldering iron2. PCB(Printed Circuit Board) with available pads

3. SMD (Surface Mount Device) component that matches the available pad

4. Solder (recommend water soluble, rosin core acceptable)

5. Desoldering braid

6. Flux w/ applicator

7. Tweezers

8. Rubbing alcohol (rosin core solder) OR

9. Water (for water soluble solder)

10. Anti-static cloth

Step one

1. Check to be sure the pad size of the PCB lines up with the pins on the SMD2. Clean the PCB of any dust or debris.

3. Turn the soldering iron on now, and set the temperature between 600-700 degrees.

Warning: When heated to these temperatures, you will be burned if you touch the tip of the soldering iron.

Step two

Align the pins of the component with the pads on the circuit board using tweezers. Since most surface mount components have the same amount of pins on both sides, it is important to find "pin 1" every time you place a new component.

Step three

1. Keep one hand still, holding the component in place with the tweezers.2. By now, the soldering iron should be hot. Get a small to medium sized dot of solder on the tip.

3. Pick any corner pin on the component

4 . Touch and hold the soldering iron to the pad that will be associated with that pin.

5. If you have done this correctly, the solder should have transferred from the pad on the circuit board to the component pin, it does not matter if you have connected excess pins, this will be fixed later.

Step four

There are 2 purposes for flux in soldering: to prevent beading of the solder, and help the solder flow from the soldering iron to the circuit board. Flux will be used on this board to limit the amount of bridged connections made, and generally make the job easier.1. This substance is messy, so be sure to use an applicator. (toothpick, brush, etc.) In this case, I have used a metal tip.

2. Get a large amount of flux on the applicator.

3. Spread the flux over the pins on the opposite side of the component that was tacked down in the previous step.

Step five

1. Pick up the soldering iron in one hand, and the solder in the other,

2. Use the soldering iron to heat up the pad, not the pin on the component.

3. While the pin is hot, position the solder between the pad and the pin. The heat will melt the solder, and the flux will cause it to flow where it needs to.

4. Repeat this as many times as necessary.

2. Use the soldering iron to heat up the pad, not the pin on the component.

3. While the pin is hot, position the solder between the pad and the pin. The heat will melt the solder, and the flux will cause it to flow where it needs to.

4. Repeat this as many times as necessary.

Step six

It is fairly common that while preforming the previous step, a solder bridge will develop. A solder bridge might look something like the picture below.

These steps will also work for removing the component from the board.

1. Take the desoldering wick and place it over the solder you want to remove.

2. With the soldering iron, lightly press on the wick, to ensure the heat is transferred through to the solder.

Warning: Remember that heat removes solder, not pressure. Too much pressure applied could remove the pad or pin on the component, ruining the component or board.

These steps will also work for removing the component from the board.

1. Take the desoldering wick and place it over the solder you want to remove.

2. With the soldering iron, lightly press on the wick, to ensure the heat is transferred through to the solder.

Warning: Remember that heat removes solder, not pressure. Too much pressure applied could remove the pad or pin on the component, ruining the component or board.

Step seven

If water soluble solder was used, replace rubbing alcohol with water.

1. Take the anti-static cloth and pour a small amount of rubbing alcohol onto it.

2. Gently clean around the newly soldered component, and where any excess flux exists. This will give a more professional look.

1. Take the anti-static cloth and pour a small amount of rubbing alcohol onto it.

2. Gently clean around the newly soldered component, and where any excess flux exists. This will give a more professional look.

I hope you have found this helpful there is also a way to use hot air that I will be sharing soon

Dobby

Monday, 29 May 2017

Circuit Monday #5 bottle llight circuit

Welcome to another Circuit Monday this week I will share the circuit from the bottle light that was in yesterdays Project Day.

I breadboarded on the prototype board I made on Project day #3 if you haven't seen it yet you can check it out here

I breadboarded on the prototype board I made on Project day #3 if you haven't seen it yet you can check it out here

Parts needed

- 100k resistor

- 2 leds

- jumper wire

Step one

Connect the 100k resistor to the + rail of the board and the other end to an empty row on the board

Step two

Connect the anode of the first led to the resistor

Step three

Connect the anode of the second led to the cathode of the first

Step four

connect a jumper wire to the cathode of the second led and the other end to the - rail of the board

Step Five

power the board if everything is connected right the leds should light up

Fritzing Layout

this is the same circuit as I used on yesterdays bottle light click here to check it out

Dobby

Another bank holiday update

Hi folks hope your all enjoying the bank holiday weekend I have been very busy I made a bottle light for yesterdays Project day and I have been working on some more content for the blog that I hope you will enjoy . I was planning on going to a carboot sale today to look for future projects but its raining cats and dogs here which is a massive pain so that will have to wait until next Sunday.

So why post this update today well I wanted to ask what you think about the content I am producing at the moment if you have any feedback please let me know I really want this to be as enjoyable for you as it is for me to write.

I am hoping to get my shed sorted soon so I don't have to keep doing all my projects in the living room where I only have limited space and tools once I'm back in the shed I will give your a tour and be able to make bigger and better Projects for you to enjoy.

the last thing Id like to talk about is the schedule at the moment I am at least posting one update a day at 5pm GMT is that working for you or should I push it back to a later time and if so what time ?

Thanks for reading

Dobby

So why post this update today well I wanted to ask what you think about the content I am producing at the moment if you have any feedback please let me know I really want this to be as enjoyable for you as it is for me to write.

I am hoping to get my shed sorted soon so I don't have to keep doing all my projects in the living room where I only have limited space and tools once I'm back in the shed I will give your a tour and be able to make bigger and better Projects for you to enjoy.

the last thing Id like to talk about is the schedule at the moment I am at least posting one update a day at 5pm GMT is that working for you or should I push it back to a later time and if so what time ?

Thanks for reading

Dobby

Sunday, 28 May 2017

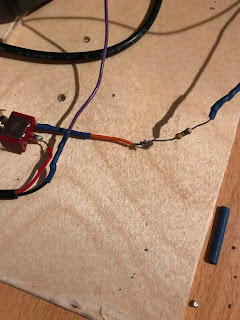

Project Day # 4 Bottle light

Hi guys and girls welcome another Project day this week due to the fact it is a bank holiday here in the U.K I thought I make a bottle light out of an empty beer bottle from a BBQ that I had yesterday evening. I feel I should say I have to make one little change to this I did have a 10k on the circuit but after completing it I found that it wasn't working so I had to remove it .

Parts needed

1 switch

2 leds

1 bottle

1 5v power supply

1 100k resistor

2 pieces of wood one big enough to fit the bottle on and one to go inside the bottle

Wire

Wire

step one

Drink a bottle of beer or glass bottled drink of choice I drank a Coors light so that's what I will be using in this project I then used a Dremel to make a hole I the bottom of the bottle (use a low speed on the Dremel and wear safety glasses)

Step two

I soldered the cathode of the first led to the anode of the second

Step three

I soldered a wire to one pin on the switch and heat shrank it

Step four

I then soldered the 100k resistor to the wire coming from the switch

Step Five

I then soldered the resistor with a wire to the anode of the led pair

Step six

I then soldered a wire from the cathode side of the led pair to the - side of the power supply.

Step seven

I then soldered the + side of the power supply onto the switch and that's the wiring competed

Step eight

I drilled a hole in the bigger piece of wood and fitted the small piece into it I held it with super glue.

Step nine

I taped the led to the top of the small piece of wood and glue the switch in place

Step ten

I placed the bottle over the top and that's the project finished it's not very bright in the daylight I post a picture of it in the dark on my twitter later on today .

improvements

I think the first improvement I would make is to paint the base then Id find a more powerful led to go in it also I would like to fit a pot so I can dim the light but I am going to use it on my bed bedside table .

hope you enjoyed this project

Dobby

Saturday, 27 May 2017

The news #4 Making the most of the long weekend

Hi all welcome to this weeks news update.

I would like to start by sending condolences to the family and friends of all the victims of the attack I'm Manchester on Monday .

this week I have had to pack up my shed and put most of my tools into storage as the roof has gone I am hoping to find somewhere else shortly It has put my projects back slightly but I will still keep my schedule and there will still be a Project day tomorrow .

I have now gotten most of my first banggood order and I am working on reviews for them which will be in a special postbox update soon so keep an eye out for that .

the next thing to mention is that I have started a page on patreon which is a way for people to support content creators like me if you'd like to support me in making better content click here .

now on to my weekend plans are in about half hour I will be watching my beloved Chelsea in the F.A cup final then I will get on to doing a few repair jobs I have got come in one of which is repairing a BBC Mirco which I featured on Flashback Friday yesterday.

Then on Sunday I will be doing the Project day which I hope you will enjoy . then I am planning to go to a carboot on Monday to look for future projects and spare parts which I will update you on as well possibly on here or my twitter @thedailydobby if you would like check that out I will be starting a facebook soon as well.

hope you have a great weekend

Dobby

I would like to start by sending condolences to the family and friends of all the victims of the attack I'm Manchester on Monday .

this week I have had to pack up my shed and put most of my tools into storage as the roof has gone I am hoping to find somewhere else shortly It has put my projects back slightly but I will still keep my schedule and there will still be a Project day tomorrow .

I have now gotten most of my first banggood order and I am working on reviews for them which will be in a special postbox update soon so keep an eye out for that .

the next thing to mention is that I have started a page on patreon which is a way for people to support content creators like me if you'd like to support me in making better content click here .

now on to my weekend plans are in about half hour I will be watching my beloved Chelsea in the F.A cup final then I will get on to doing a few repair jobs I have got come in one of which is repairing a BBC Mirco which I featured on Flashback Friday yesterday.

Then on Sunday I will be doing the Project day which I hope you will enjoy . then I am planning to go to a carboot on Monday to look for future projects and spare parts which I will update you on as well possibly on here or my twitter @thedailydobby if you would like check that out I will be starting a facebook soon as well.

hope you have a great weekend

Dobby

Friday, 26 May 2017

Flashback Friday #4 BBC Micro

The BBC Microcomputer System, or BBC Micro, is a series of microcomputers and associated peripherals designed and built by the Acorn Computer company for the BBC Computer Literacy Project, operated by the British Broadcasting Corporation. Designed with an emphasis on education, it was notable for its ruggedness, expandability, and the quality of its operating system. An accompanying 1982 television series "The Computer Programme" featuring Chris Serle learning to use the machine was also broadcast on BBC 2.

After the Literacy Project's call for bids for a computer to accompany the TV programmes and literature, Acorn won the contract with the Proton, a successor of its Atom computer prototyped at short notice. Renamed the BBC Micro, the system was adopted by most schools in the United Kingdom, changing Acorn's fortunes. It was also moderately successful as a home computer in the UK despite its high cost. Acorn also employed the machine to simulate and develop the ARM architecture which, many years later, has become hugely successful for embedded systems, including tablets and cellphones. In 2013 ARM was the most widely used 32-bit instruction set architecture.

While nine models were eventually produced with the BBC brand, the phrase "BBC Micro" is usually used colloquially to refer to the first six (Model A, B, B+64, B+128, Master 128, and Master Compact), excluding the Acorn Electron; subsequent BBC models are considered as part of Acorn's Archimedes series.

History

During the early 1980s, the BBC started what became known as the BBC Computer Literacy Project. The project was initiated partly in response to an ITV documentary series The Mighty Micro, in which Dr Christopher Evans of the UK's National Physical Laboratory predicted the coming microcomputer revolution and its effect on the economy, industry, and lifestyle of the United Kingdom.

The BBC wanted to base its project on a microcomputer capable of performing various tasks which they could then demonstrate in the TV series The Computer Programme. The list of topics included programming, graphics, sound and music, teletext, controlling external hardware, and artificial intelligence. It developed an ambitious specification for a BBC computer, and discussed the project with several companies including Acorn Computers, Sinclair Research, Newbury Laboratories, Tangerine Computer Systems, and Dragon Data.

The Acorn team had already been working on a successor to their existing Atom microcomputer. Known as the Proton, it included better graphics and a faster 2 MHz MOS Technology 6502 central processing unit. The machine was only at the design stage at the time, and the Acorn team, including Steve Furber and Sophie Wilson, had one week to build a working prototype from the sketched designs. The team worked through the night to get a working Proton together to show the BBC. Not only was the Acorn Proton the only machine to match the BBC's specification, it also exceeded it in nearly every parameter. Based on the Proton prototype the BBC signed a contract with Acorn as early as February 1981; by June the BBC Micro's specifications and pricing were decided.

Software and expandability

The BBC Micro platform amassed a large software base of both games and educational programs for its two main uses as a home and educational computer. Notable examples of each include the original release of Elite and Granny's Garden. Programming languages and some applications were supplied on ROM chips to be installed on the motherboard. These loaded instantly and left the RAM free for programs or documents.Although appropriate content was little-supported by television broadcasters, telesoftware could be downloaded via the optional Teletext Adapter and the third-party teletext adaptors that emerged.

The built-in operating system, Acorn MOS, provided an extensive API to interface with all standard peripherals, ROM-based software and the screen.Features private to some versions of BASIC, like vector graphics, keyboard macros, cursor-based editing, sound queues and envelopes, were placed in the MOS ROM and made available to any application. BBC BASIC itself, being in a separate ROM, could be replaced with any equivalent language.

BASIC, other languages and utility ROM chips resided in any of four 16 KB paged ROM sockets, with OS support for sixteen sockets via expansion hardware. The five (total) sockets were located partially obscured under the keyboard, with the leftmost socket hard-wired for the OS. While the original usage for the perforated panel on the left of the keyboard was for a Serial ROM or Speech ROM, a ZIF socket or edgecard connector could be installed in that location instead. The socket could be connected to one of the empty Sideways/PagedROM sockets via a header cable. The paged ROM system was essentially modular. A language-independent system of star commands, prefixed with an asterisk, provided the ability to select a language (for example *BASIC, *PASCAL), a filing system (*TAPE, *DISC), change settings (*FX, *OPT) or carry out ROM-supplied tasks (*COPY, *BACKUP) from the command line. The MOS recognised a handful of built-in commands, and polled the paged ROMs in descending order for service otherwise; if none of them claimed the command then the OS returned a Bad command error. Connecting an external EPROM programmer, one could write extensive programs, copy to programmable ROM (PROM) or EPROM, then invoke them without taxing user memory.

Not all ROMs offered star commands (ROMs containing data files, for instance), but any ROM could "hook" into certain vectors to enhance the system's functionality. Often the ROM was a device driver for mass storage combined with a filing system, starting with Acorn's 1982 Disc Filing System whose API became the de facto standard for floppy disc access. The Acorn Graphics Extension ROM (GXR) expanded the VDU routines to draw geometric shapes, flood fills and sprites. During 1985 Micro Power designed and marketed a Basic Extension ROM, introducing statements such as WHILE, ENDWHILE, CASE, WHEN, OTHERWISE, and ENDCASE, as well as direct mode commands including VERIFY.

Acorn strongly discouraged programmers from directly accessing the system variables and hardware, favouring official system calls.This was ostensibly to make sure programs kept working when migrated to coprocessors that utilised the Tube interface, but it also made BBC Micro software more portable across the Acorn range. Whereas untrappable PEEKs and POKEs were commonly used by other computers to reach the system elements, programs in either machine code or BBC BASIC would instead pass parameters to an operating system routine. In this way the MOS could translate the request for the local machine or send it across the Tube interface, as direct access was impossible from the coprocessor. Published programs largely conformed to the API except for games, which routinely engaged with the hardware for greater speed, and thus required a particular Acorn model.

As the early BBC Micros had ample I/O allowing machines to be interconnected, and as many schools and universities employed the machines in Econet networks, numerous networked multiplayer games were created. With the exception of a tank game, Bolo, few became popular, in no small measure due to the limited number of machines aggregated in one place. A relatively late but well documented example can be found in a dissertation based on a ringed RS-423 interconnect.

Peripherals

In line with its ethos of expandability Acorn produced its own range of peripherals for the BBC Micro, including:- Joysticks

- Tape recorder

- Floppy drive interface upgrade

- Floppy drives (single and double)

- Econet networking upgrade

- Econet Bridge

- Winchester disk system

- 6502 Second Processor

- Z80 Second processor (with CP/M and business software suite)

- 32016 Second processor

- ARM Evaluation System

- Teletext adapter

- Prestel adapter

- Speech synthesiser

- Music 500 synthesiser

- BBC Turtle (robot)

- BBC Buggy

- IEEE 488 Interface

- RGB monitors

- Printers, plotters

- Modems

BBC BASIC built-in programming language

The built-in ROM-resident BBC BASIC programming language interpreter realised the system's educational emphasis and was key to its success; not only was it the most comprehensive BASIC compared to other contemporary implementations but it ran very efficiently and was therefore fast. Advanced programs could be written without resorting to non-structured programming or machine code (necessary with many competing computers). Should one want or need to do some assembly programming, BBC BASIC featured a built-in assembler that allowed a very easy mixture of BBC BASIC and assembler for whatever processor BBC BASIC was operating on.When the BBC Micro was released, many competing home computers used Microsoft BASIC, or variants typically designed to resemble it. Compared to Microsoft BASIC, BBC BASIC featured IF…THEN…ELSE, REPEAT…UNTIL, named procedures and functions, but retained Goto and GOSUB for compatibility. It also supported high-resolution graphics, four-channel sound, pointer-based memory access (borrowed from BCPL) and rudimentary macro assembly. Long variable names were accepted and distinguished completely, not just by the first two characters.

Other languages

Acorn had made a point of not just supporting BBC Basic but a number of contemporary languages, some of which were supplied as ROM chips to fit the spare 'Sideways-ROM' sockets on the motherboard. Other languages were supplied on tape or disk based.Programming Languages from Acorn:

- ISO Pascal (2× 16 KB ROM + floppy disk)

- S-Pascal (disk or tape)

- BCPL (ROM plus further optional disk based modules)

- Forth (16 KB ROM)

- LISP (disk,tape or ROM)

- Logo (2× 16 KB ROM)

- Turtle Graphics (disk or tape)

- Micro-PROLOG (16 KB ROM)

- COMAL (16 KB ROM)

- Microfocus CIS COBOL (running under CP/M on floppy disks via the Z80 second processor)

Other Hobbies

I have been asked by a few of you to share my other hobbies so here we go

I am a football(soccer) fan my team is Chelsea I have been a fan of them for my whole life so I like to play and watch football .

I also enjoy manga and anime I'm a big fan of one piece and bleach but I watch most anime that I find interesting I am reading attack on titan at the moment .

I'm also a massive batman fan I will read or watch anything to do with him I really enjoy reading to be honest .

I also like to meet and going out with my friends

I enjoy a the cinema as well so

as you can see I have a lot of hobbies beside my main interest of electronics and tech

Dobby

I am a football(soccer) fan my team is Chelsea I have been a fan of them for my whole life so I like to play and watch football .

I also enjoy manga and anime I'm a big fan of one piece and bleach but I watch most anime that I find interesting I am reading attack on titan at the moment .

I'm also a massive batman fan I will read or watch anything to do with him I really enjoy reading to be honest .

I also like to meet and going out with my friends

I enjoy a the cinema as well so

as you can see I have a lot of hobbies beside my main interest of electronics and tech

Dobby

Thursday, 25 May 2017

Toolbox Thursday #4 USB Soldering Iron

this week I though I would change this instead of reviewing a set of tools like I have been for I though it would be better to review that the tools that I'm using and getting in the post if you like this change please let me know.

on the reviews the first thing I will talk about is what its like to setup then I will move on what its like to use and to where you can get one from (there may be an affiliate link if you would like to help me out ) and if its good value for money and the last thing in the review will be my overall rating of the item it will be a 5 star system with 1 being the lowest and 5 being the highest I hope that will help you understand how I will be review items from now on.

get

on the reviews the first thing I will talk about is what its like to setup then I will move on what its like to use and to where you can get one from (there may be an affiliate link if you would like to help me out ) and if its good value for money and the last thing in the review will be my overall rating of the item it will be a 5 star system with 1 being the lowest and 5 being the highest I hope that will help you understand how I will be review items from now on.

get

Setup

Setup is really simple for this all you have to do is plug in the USB cable into it and plug the other end into a power bank or a USB plug I tried both out and its performance was the same.Testing

To start the iron you have to hold the sensor switch which for me was very easy and comfortable as it is the same spot I would normally hold my irons for some people It may be a bit of a problem but not that much of one.

Heating the iron up(I am not sure how hot the tip gets as I don't have a tip tester yet ) happens very quickly and tinning the tip ( you need to tin the tip on new soldering irons and before every use )was very smooth and it flowed well to be honest I was surprised by how well it handled solder I tested from 0.3 to 2.0mm solder with it and it performed well on all of it.

now for its soldering performance I soldered two 2mm wires together and it handled that fine it did struggle with 5mm wire I the moved on to soldering a simple circuit board and it did that perfectly although it does struggle with big components but I was impressed with it .

Where can you one

there are a few places you can this from there which I will list below . As for value for money the one I brought cost me £6.00 and I think it was well worth the purchase.

Banggood this is the Affiliate link which means I would get a few pence for it.

Overall Rating

I was very impressed with this iron I can see myself using this for little jobs that I wouldn't want to heat up my main iron it performed better than I thought it would on all my tests so I'm going to give it 4* out of a possible 5* I recommend picking one up .

that's all for today I hope you comeback tomorrow for Flashback Friday

Do

On Patreon

Hi guys just a quick update to let you know I have started a Patreon check out the link if you would like to know more

Wednesday, 24 May 2017

What's in the postbox #4

welcome to this weeks what's in the postbox.

this weeks postbox is a mixed bag there are a few nice items .

this weeks postbox is a mixed bag there are a few nice items .

Item 1

The first item is 5 CR2032 batteries to go with the a set of battery holders that I ordered they just haven't shown up yet I have used one of the batteries to test so leds .

Item 2

the second is a mini Arduino board the main idea I have for this at the moment is to make and run a small light and sound circuit I am working on with a few different modes that can be switched between check back at a later date for that project.

Item 3

The third item is a small surface mount practice board for me to practice surface mounting components I mainly have this to try a heat gun method that I have been shown I will update with my progress.

Item 4

the fourth item today is a set of small wire cutters they work really well on component leads and small wires that can be tricky to cut with bigger wire cutters I will give full review of the in a future Toolbox Thursday.

Item 5

now on to the next item that is a carbon filter for the solder fume exactor project I got them to help with removing harmful fumes.

Item 6

the sixth item is a small box of flux that I picked up because I was getting low on flux and it was cheap I haven't used it yet but I'm sure it will do the job.

Item 7

the next item on the list is a step down circuit that is rated from 3- 40volts input and 1-35volts output the main reason I got this was to reduce a 19volt power supply I have down to 9volts so it can safely run a radio I have.

Item 8

the eighth Item is a USB powered soldering iron that is going to shown in more detail in tomorrows Toolbox Thursday so check back to see a review .

Item 9

The last item is a set of anti-static tweezers I they are made of plastic for seem to work really well I picked up a few surface mount components and removed some small ribbon connectors inside an phone that I repaired for a friend so very pleased to add these to my ever growing tweezer collection .

Thanks for checking out this weeks postbag

Dobby

Potentiometers

A potentiometer, or pot, is a variable resistor. A small one used for internal circuit adjustments is called a trimpot. Pots and trimpots may have two, three or (rarely) four leads, but most have three. The outer two are connected to the substrate on which the resistive element is formed, with one lead at each end of the resistor. The center lead goes to the wiper, a movable metal contact whose point touches the resistive element, selecting a resistance value that rises relative to one outer lead while falling relative to the other as you turn the knob. A two-wire pot has no connection to one end of the resistive element but is otherwise the same. Some two-wire pots connect the free end of the element to the wiper, which slightly affects the resistance curve as you turn it, but it doesn’t matter a whole lot. Two-wire pots are sometimes called rheostats.Four-wire pots, used mostly on stereo receivers to provide the “loudness” function which increases bass at low volume levels, are like three-wire pots, but with an extra tap partway up the resistive element. The amount of resistance change you get per degree of rotation is even from end to end on linear taper pots. On log taper pots, also called audio taper, a logarithmic resistance curve is used, so that audio loudness, which is perceived on a log curve, will seem to increase or decrease at a constant rate as the control is varied. Trimpots, whose primary use is for set-and-forget internal adjustments on circuit boards, are always linear taper. How much power the pot can dissipate depends on its size. It’s not marked on the part. In most applications, only small signals are applied to it, so it’s not much of an issue. Some pots have metal shafts, while others use plastic. Plastic provides insulation in applications like power supplies, where you might come in contact with a dangerous voltage. Also, some pots have switches built into them, and those may be rotary, operating at one end of the wiper’s travel, or push-pull. Most trimpots rotate through less than 360 degrees, just like pots. Those used in applications requiring high precision may be multi-turn, with a threaded gear inside providing the reduction ratio. Multi-turn trimpots use a small screw for adjustment, usually off to one side of the body of the component. Be wary of turning the screw, because there’s no visual indicator to help you set it back where it was. In stereo receivers, pots can be ganged together onto one shaft, so that turning it will affect both channels together. Each pot is internally isolated from the other, though you may find one end of all of them tied to ground at the terminals.

Test the outer two leads on a three-lead pot with your DMM’s ohms scale. It should read something close to the printed value. If the element is cracked, it’ll read open. To check for integrity of the wiper’s contact, connect the meter between one end of the pot and the wiper. Slowly turn the pot through its range, observing the change in resistance. This is one test better done with a good old analog VOM; the meter needle will swing back and forth with the position of the wiper, and it’s easy to interpret. A two-lead pot should read something close to its stated resistance at one end of its control range and 0 ohms at the other. To verify if a pot is linear taper or log taper, measure the resistance at one-third of the rotation and again at two-thirds. See if those values are about one-third and two-thirds of the total resistance from end to end. If it’s a log taper part, they won’t even be close.

Markings

Pots are numerically marked with their resistance values using the same scheme as resistors. A B in the code indicates a linear pot, while a C means a log pot. An A, though, can mean either, as the codes have changed over the years. Some pots have LIN or LOG printed on them. Most don’t, though.Uses

Pots are used to adjust operating parameters for analog signals and power supply voltages. Once, they were the primary method of setting just about everything. In this digital age, volume, treble, bass, brightness, contrast and such are more often selected from a menu or adjusted with up/down buttons. Trimpots on circuit boards are less common too, but you’ll still find some, especially in power supplies, including switchers.What Kills Them

Out-of-Circuit Testing

Test the outer two leads on a three-lead pot with your DMM’s ohms scale. It should read something close to the printed value. If the element is cracked, it’ll read open. To check for integrity of the wiper’s contact, connect the meter between one end of the pot and the wiper. Slowly turn the pot through its range, observing the change in resistance. This is one test better done with a good old analog VOM; the meter needle will swing back and forth with the position of the wiper, and it’s easy to interpret. A two-lead pot should read something close to its stated resistance at one end of its control range and 0 ohms at the other. To verify if a pot is linear taper or log taper, measure the resistance at one-third of the rotation and again at two-thirds. See if those values are about one-third and two-thirds of the total resistance from end to end. If it’s a log taper part, they won’t even be close.

Tuesday, 23 May 2017

Training Tuesday #4 Progarm an attiny

welcome to this Training Tuesday this week I thought I would share how to program an AT tiny using an Arduino board hopefully you will find this helpful .

By default the Arduino IDE does not support the ATtiny85 it's required to add support for the Attiny85 to the Arduino Board Manager:

https://raw.githubusercontent.com/damellis/attiny/ide-1.6.x-boards-manager/package_damellis_attiny_index.json

Arduino Uno – ATtiny85

what we want is to be able to program the ATtiny85 from the Arduino IDE which requires to burn the bootloader to the ATtiny85 we will need to prep the Arduino fist by uploading the ISP sketch to it.

In the Arduino IDE select File-->Examples--> 11. Arduino ISP-->ArduinoISP

the ISP sketch should open and upload it to your Arduino Uno

Now open the Blink example from arduino examples and change the pin number from 13 to 0 and upload.

Now its time to test. Remove all connections from Arduino and take a power source. Here I will use a 3volt battery holder to power ATtiny85

There it is the blink program running on a ATtiny85 with just a battery to power it. You can do many projects with low cost, low power and low space. Only your imagination is the limit here.

hope you found this helpful see you tomorrow for What's in the postbox

Dobby

Getting started

To program the ATtiny85 we need to first set Arduino Uno in ISP mode. Connect your Arduino Uno to the PC. Open Arduino IDE and open the ArduinoISP example file (File -> Examples -> ArduinoISP) and upload it

By default the Arduino IDE does not support the ATtiny85 it's required to add support for the Attiny85 to the Arduino Board Manager:

From the Arduino IDE Go to Arduino->Preferences then scroll down to Additional Board Managers URLs

Copy & paste the following (if you already have a board manager URL just add a comma before pasting)

https://raw.githubusercontent.com/damellis/attiny/ide-1.6.x-boards-manager/package_damellis_attiny_index.json

Press ok at

the bottom then restart the Arduino IDE

Connecting ATtiny85 with Arduino Uno

Now with all the above things ready we will start programming the attiny85. Connect the arduino uno to attiny85 using breadboard as below.Arduino Uno – ATtiny85

- 5V – Vcc

- Gnd – Gnd

- Pin 13 – Pin 2

- Pin 12 – Pin 1

- Pin 11 – Pin 0

- Pin 10 – Reset

add a 10uF capacitor between RESET and GND in Arduino. This is to avoid Arduino from being auto reset when we upload the program to attiny85. If you are using a electrolytic capacitor make sure the anode goes in GND of Uno.

prep the Arduino

what we want is to be able to program the ATtiny85 from the Arduino IDE which requires to burn the bootloader to the ATtiny85 we will need to prep the Arduino fist by uploading the ISP sketch to it.

In the Arduino IDE select File-->Examples--> 11. Arduino ISP-->ArduinoISP

the ISP sketch should open and upload it to your Arduino Uno

Uploading program to ATtiny85

Now back to Arduino IDE. Select ATtiny under Tools -> Board. Then select ATtiny85 under Tools -> Processor. And select 8 MHz (internal) under Tools -> Clock.Then make sure Arduino as ISP is selected under Tools -> Programmer By default the ATtiny85 runs at 1MHz. To make it to run at 8MHz select Tools -> Burn Bootloader. if burning bootloader was successful you will see a message on the screen.Now open the Blink example from arduino examples and change the pin number from 13 to 0 and upload.

Now its time to test. Remove all connections from Arduino and take a power source. Here I will use a 3volt battery holder to power ATtiny85

There it is the blink program running on a ATtiny85 with just a battery to power it. You can do many projects with low cost, low power and low space. Only your imagination is the limit here.

hope you found this helpful see you tomorrow for What's in the postbox

Dobby

Monday, 22 May 2017

Circuit Monday #4 555 flashing led

Welcome to Circuit Monday this weeks circuit is a using a led to make an led flash .

this was built on the prototyping board that I made in yesterdays Project Day #3

here is the layout I made on Fritzing which is really useful software if you haven't checked it out I suggest you take a look.

thanks for reading see you tomorrow for Training Tuesday

Dobby

this was built on the prototyping board that I made in yesterdays Project Day #3

Parts needed

1 X 555timer

1X resistor

1Xled

Step 1

place 555timer on the board

Step 2

connect pin 2 of the 555 to pin 6 with a jumper wireStep 3

connect pin one to - rail of the board

Step 4

Connect pin 4 to the + rail o

Step 5

connect pin 8 to the + rail

Step 6

connect pin 6 and pin 7 with a jumper and

Step 7

connect the resistor to pin 7 and the + rail

Step 8

connect the capacitor to pin1 and pin2 making sure the negative side is in pin 1

Step 9

connect a jumper wire to pin 3 and a empty row on the board

Step 10

connect the cathode of the led to the same row as the jumper wire coming from pin 3

Step 11

connect the anode side of the led to the + rail and power the circuit

the led will flash every few moments depending on the values of the capacitor and resistor

Fritzing layouts

thanks for reading see you tomorrow for Training Tuesday

Dobby

Subscribe to:

Comments (Atom)

dobby repairs

Hi everyone I know that I haven't posted on here for quite some time I probably won't be posting on here again for a while but I wa...

-

hi guys I just wanted to share this Electrical Contact Cleaner I got from ebay to it works really well and does the job

-

welcome and happy Project day this week it is a Prototyping board for bread boarding this was just a quick little project to give me an eas...

-

Hi Folks today I am going to share a quick teardown of a Sgnalex Powerbank I got from Poundland yesterday. As you can see from the above...